1. The use of the RO membrane-specific scale inhibitor should be based on water quality and system process conditions to determine the dosage, typically controlled between 3 and 5 ppm, with continuous dosing.

2. The following formula can be used to calculate the volume of SM-3210R standard solution to be added to the dosing tank:U=Q×a×V/1000×ρ×X

Where:

U is the volume of standard solution to be added (L)

Q is the RO feed water flow rate (T/h)

a is the dosage of the agent (ppm, g/T) (standard solution)

V is the effective volume of the dosing tank (L)

ρ is the density of the standard solution (g/L)

X is the actual output of the dosing metering pump (L/h)

1000 is the unit conversion factor (g/kg)

-

Reverse Osmosis Membrane Special Anti-Scaling Agent

The SM-3210R membrane scale inhibitor is a high-efficiency scale inhibitor and dispersant designed for use in reverse osmosis (RO) systems as well as nanofiltration (NF) and ultrafiltration (UF) systems. It prevents membrane scaling, increases water production and quality, and reduces operating costs.

1.The RO membrane-specific scale inhibitor effectively controls inorganic scaling over a wide concentration range, with a LSI allowable value of 2.8 without acid addition.

1. It does not form insoluble compounds with iron, aluminum oxides, or silicon compounds and effectively inhibits silica deposition, allowing SiO2 levels up to 290 ppm on the concentrate side while effectively controlling iron, aluminum, and heavy metal contamination.

2. This scale inhibitor is suitable for use with RO CA and TFC membranes, NF membranes, and UF membranes.

3. It has solubility, compatibility, and stability, and is effective at feed water pH values between 5 and 10.

4. At low dosages, it effectively controls types of scaling, including calcium carbonate, calcium sulfate, barium sulfate, strontium sulfate, iron hydroxide, aluminum hydroxide, and silica.BENEFITS & FEATURES

Get a QuoteProduct Code SM-3210 membrane scale inhibitor

Appearance Transparent and homogeneous amber-coloured liquid

Proportion 1.20±0.05

pH value (1% aqueous solution) 1.5~2.5

Since 1991

Changzhou SanmingJingHui Environmental Protection Technology Co., Ltd.

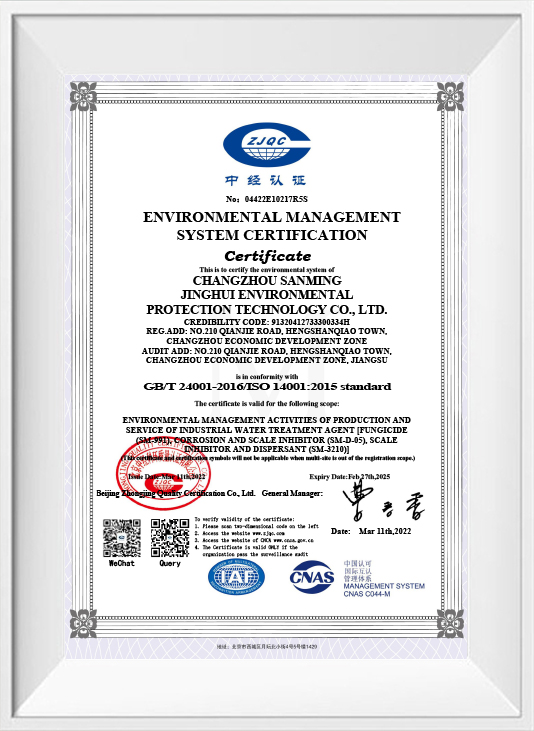

Changzhou SanmingJingHui Environmental Protection Technology Co., Ltd. (formerly Changzhou Sanming Chemical Co., Ltd.) is China Reverse Osmosis Membrane Special Anti-Scaling Agent Suppliers and OEM/ODM Reverse Osmosis Membrane Special Anti-Scaling Agent manufacturers, a high-tech, environmentally friendly and energy-saving water treatment agent professional enterprise integrating scientific research and development, production and sales, and technical services. It was founded in 1991.

The company is located in the central area of the Yangtze River Delta, close to the Shanghai-Nanjing Railway and the Beijing-Hangzhou Grand Canal, and is located in Hengshanqiao Town, the middle intersection of the Shanghai-Nanjing Expressway. It is only half an hour away from Changzhou Civil Aviation Airport and has convenient transportation. It has fixed assets of more than 18 million yuan, more than 20 scientific researchers, and 25% of employees have obtained various professional and technical titles.

-

A chemical treatment establishment is a facility (or dedicated plant area) that conditions water, wastewater, or process streams using reagents such as coagulants, acids/alkalis, oxidants, or specialt...

READ MORE -

Introduction to Industrial Water Treatment Chemicals Industrial water treatment chemicals are substances used to improve water quality and address various challenges faced by industries in managing wa...

READ MORE -

What Is Polyaluminum Chloride Coagulant and How Does It Work? Polyaluminum chloride coagulant, often abbreviated as PAC, is an inorganic polymer coagulant widely used in drinking water, industrial wat...

READ MORE

More product information

Historical Challenges and Solutions in Managing Scaling in Reverse Osmosis Membranes

Reverse osmosis (RO) technology has revolutionized water purification, but managing scaling has always been a significant challenge. Historically, scaling issues arose from the deposition of minerals like calcium carbonate and silica on RO membranes, leading to decreased efficiency and increased maintenance costs. Early solutions included periodic chemical cleaning and the use of various scale control agents, but these methods often proved inadequate for comprehensive scaling control.

As the demand for high-purity water increased, innovations in reverse osmosis membrane special anti-scaling agents emerged. Early formulations focused on acid-based solutions, which could effectively dissolve scales but required careful handling and frequent application. Over time, the industry developed more advanced scale inhibitors that offer broader protection without the need for harsh chemicals. These modern agents are designed to be effective across a wide range of pH levels and can manage complex scale formations, including silica and heavy metals.

One notable advancement is the SM-3210R membrane scale inhibitor, a high-efficiency product specifically designed for RO systems. This anti-scaling agent stands out due to its ability to control scaling across various mineral types, including calcium carbonate, barium sulfate, and silica, even in challenging water conditions. Unlike earlier agents, SM-3210R prevents the formation of insoluble compounds with iron and aluminum, which enhances membrane longevity and reduces the frequency of cleaning cycles. Its compatibility with different membrane types and stability in a broad pH range make it a versatile choice for modern RO systems.

While the management of scaling in RO systems has historically posed challenges, the development of sophisticated anti-scaling agents like SM-3210R represents a significant leap forward.

Economic Impact of Scale Control on RO System Efficiency and Maintenance Costs

Effective scale control is crucial for optimizing the economic performance of reverse osmosis (RO) systems. Scaling, caused by mineral deposits such as calcium carbonate and silica, can severely impact RO system efficiency by reducing water production rates and increasing energy consumption. This deterioration leads to higher operational and maintenance costs, including frequent cleaning, membrane replacements, and potential downtime.

The SM-3210R membrane scale inhibitor developed specifically for RO systems, it effectively prevents the formation of scale across a broad spectrum of minerals and contaminants. By maintaining optimal membrane performance and reducing scaling, SM-3210R minimizes the need for frequent chemical cleaning and membrane replacements. This not only extends the lifespan of the RO membranes but also lowers overall maintenance costs.

Incorporating high-efficiency scale inhibitors like SM-3210R results in more stable system operation and reduced long-term expenses. The product's compatibility with various membrane types and stability across different pH levels ensures consistent performance, directly translating to cost savings and enhanced system reliability.

Effective scale control through advanced agents like SM-3210R leads to significant economic benefits by improving RO system efficiency and reducing maintenance costs. This approach underscores the importance of investing in high-quality anti-scaling solutions to achieve long-term operational and financial gains.

En

En

عربى

عربى 中文简体

中文简体